Forward deployed inventory (FDI) refers to the strategic placement of inventory in locations that are closer to end customers or key markets, as opposed to centralizing inventory in a single location. FDI allows companies to position inventory in regional or local facilities, closer to where products are in demand.

SAME DAY SERVICE & FORWARD DEPLOYED INVENTORY

FDI is important in supply chain management for several reasons.

Faster delivery times: By placing inventory in locations that are closer to end customers or key markets, FDI enables faster delivery times. This can lead to improved customer satisfaction and loyalty, as customers receive their orders more quickly, resulting in reduced transit times and improved order fulfillment.

Improved customer service: FDI allows companies to meet customer demands for quicker order fulfillment and reduced stockouts. By having inventory closer to end customers, companies can respond more quickly to customer orders and ensuring timely product availability.

Cost savings: FDI can lead to cost savings by optimizing transportation costs, inventory levels, and minimizing stockouts and overstocks. By positioning inventory in strategic locations, companies can reduce transportation costs by leveraging regional or local transportation networks and optimize inventory levels.

Enhanced flexibility: FDI increases supply chain flexibility and agility by allowing companies to respond more quickly to changes in demand, supply disruptions, or market fluctuations. By having inventory strategically positioned in multiple locations, companies can better adapt to changing market conditions and respond to unexpected events, such as supply disruptions or changes in demand patterns.

FDI relevance in today’s business landscape.

Forward deployed inventory (FDI) is relevant in today’s business landscape for several reasons:

Rapidly changing customer expectations: In today’s fast-paced business environment, customers expect faster order fulfillment and shorter delivery times. FDI allows companies to position inventory closer to end customers or key markets, resulting in faster delivery times and improved customer satisfaction.

Service providers: Service providers that need to have equipment or supplies on hand to perform their services may also use FDI. This can include businesses such as field service companies and medical services and supply providers. These companies can have service requirements of four to six hours and need to have inventory and assets in the market with the equipment and customers that they support.

E-commerce and omni-channel retailing: The rise of e-commerce and omni-

Globalization and regionalization of supply chains: Many companies today operate in global markets and have complex supply chains spanning multiple regions or countries. FDI allows companies to optimize their supply chain operations by placing inventory in regional or local facilities, closer to demand, which can help reduce transportation costs, improve responsiveness, and minimize supply chain risks.

Supply chain disruptions and uncertainties: Global events such as natural disasters, geopolitical tensions, trade disputes, and pandemics can disrupt supply chains and impact product availability. FDI can help mitigate such risks by positioning inventory in multiple locations, reducing reliance on a single source, and providing alternate supply options to ensure continuity of operations during supply chain disruptions or uncertainties.

Demand volatility and seasonality: Demand patterns can be volatile and subject to seasonality in many industries. FDI allows companies to position inventory in locations that are strategically aligned with demand patterns, helping them to better respond to changes in demand, manage seasonality, and optimize inventory levels.

Emphasis on customer experience: Today’s businesses are highly focused on providing superior customer experiences. FDI allows companies to optimize their supply chains and provide faster order fulfillment, improved product availability, and enhanced customer service, leading to better customer satisfaction and loyalty.

Challenges of Forward Deployed Inventory (FDI)

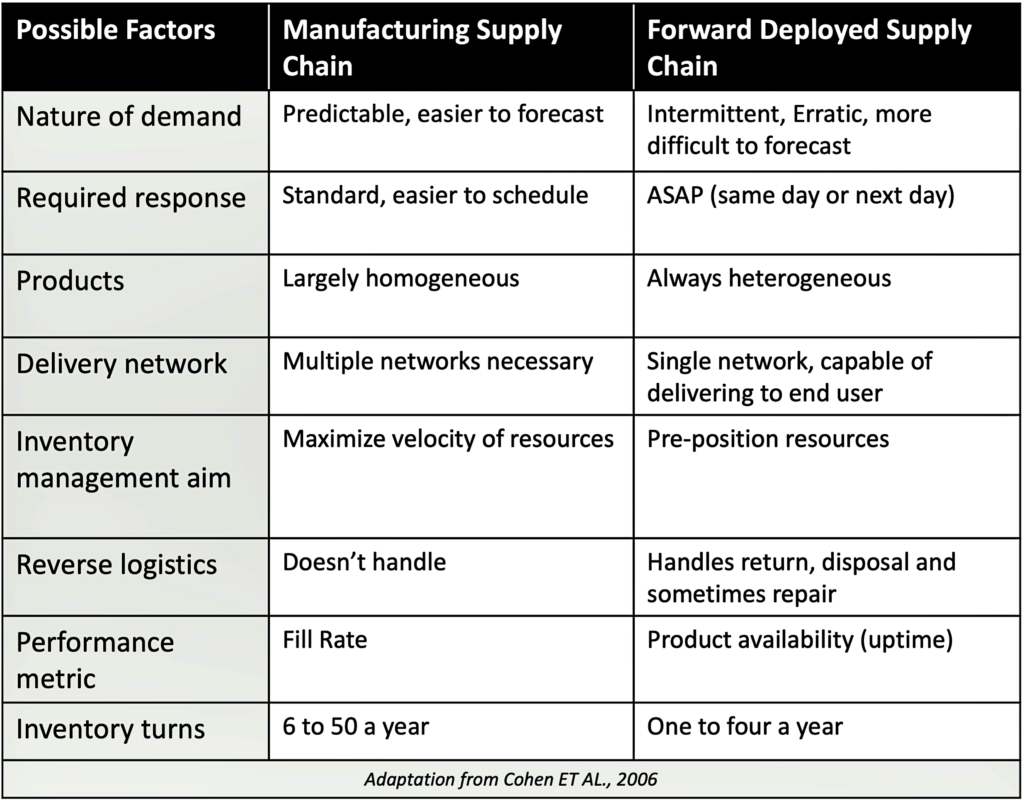

Inventory management philosophy, techniques, processes, and education have been built during the growth of manufacturing. These principles were built to optimize the manufacturing supply chain with the best understanding of the market and technology that was available at the time. They have been very successful for decades and are prominent in educating supply chain engineers. For a forward deployed supply chain some of these principles are not effective and sometimes harmful to the management of FDI.

This is because the nature of a FDI supply chain is different than a traditional manufacturing supply chain.

Inventory management for a FDI

The inventory system needs an inventory optimization based on the aim of pre-positioning of resources without exceeding the inventory holding budget. The inventory optimization needs to consider the service to the customer and the inventory budget of the organization.

The ability to fulfil orders from the most optimal location and coordination of the replenishment to right location at the optimal quantity in real-time is a significant challenge. If the orders are fulfilled from the wrong location, it can add cost of the last-mile transportation and cause service failures. If replenishment is not done at the right time and quantity, increase cost of inventory will occur or service failures will result.

Supply chain disruptions can be difficult to manage and with FDI it has its own challenges. Even though FDI has the flexibility to fulfil from more locations during an emergency the coordination of order routing is critical.

Best Practices for Implementing Forward Deployed Inventory (FDI)

The first step to implementing FDI is a location optimization. Finding the most optimal locations based on your organization’s orders will reduce the cost and increase the service. Even if you currently have locations, it is important to periodically review to see if improvement in cost and service is worth the cost of the change.

After the locations are determined, an FDI inventory optimization is necessary to determine what inventory items to put in each location and at what quantity. During this process the service requirements and inventory budget is a major consideration.

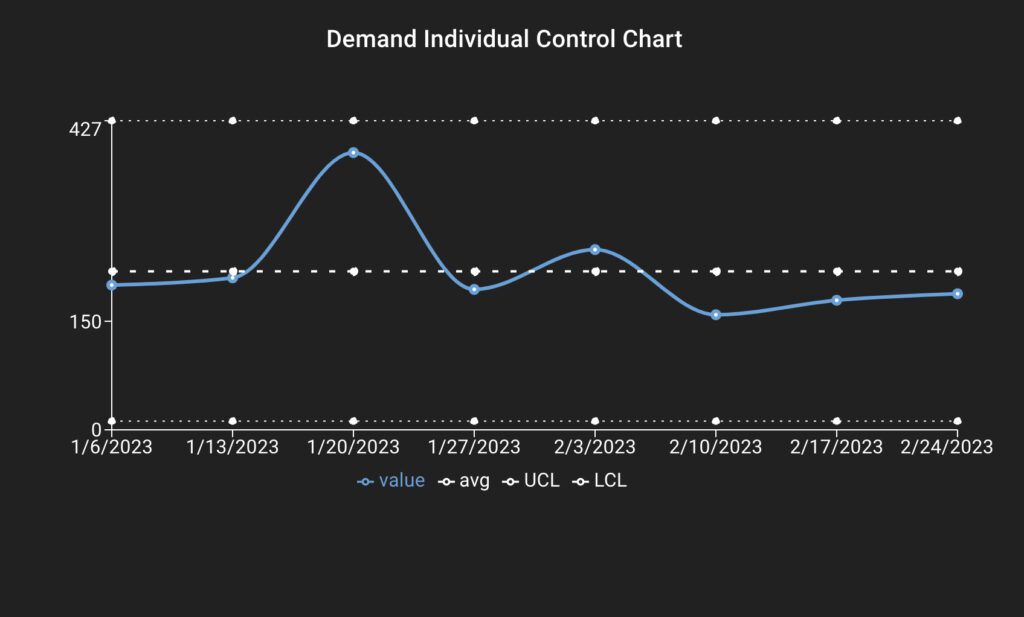

After the locations and inventory plan is complete it is recommended that a simulation be performed to test the robustness and requirements of the FDI plan. Also, the simulation can test the sensitivity of the plan against changes to the environment, such as shifts in demand.

Operations:

To get the most out of a properly designed FDI supply chain new technologies such as IoT devices, blockchain, AI, and can all help optimize a forward deployed inventory supply chain by providing valuable data and improving logistics operations.

Utilizing new technologies to fulfil orders from the most optimal locations in real time allows a better result that was not possible a few years ago.

Replenishment at the right quantity to the right

Performance metrics are key to successfully measuring the effectiveness of the system and the sources of failures. A set of metrics are necessary to quickly focus on corrective actions that saves time resolving FDI issues.

Summary

FDI can help improve customer service, reduce transit times, optimize inventory levels, enhance flexibility, and potentially result in cost savings, making it an important strategy in supply chain management for companies looking to improve their supply chain performance and meet customer demands more effectively.

FDI is relevant in today’s business landscape due to changing customer expectations, the rise of e-commerce and omni-channel retailing, globalization and regionalization of supply chains, supply chain disruptions, demand volatility, and the emphasis on customer experience. Implementing FDI can help companies enhance their supply chain performance, improve customer service, and remain competitive in today’s dynamic business environment.

FDI has challenges that requires careful planning, execution, and adaptation. Without careful planning increase cost and service failures will occur.

By adopting best practices, FDI supply chain managers can overcome the challenges and enhance their ability to manage inventory effectively and efficiently in many locations, thereby improving cost and service.

Edon Connect and Forward Deployed Inventory (FDI)

Edon Connect is a company that delivers solutions for FDI supply chains. They do this through the Edon Connect Platform and Edon Connect Operations. The Edon Connect engagement process helps companies evaluate a change to their supply chain with a small investment in time and cost.

Edon Connect Platform

Edon Connect Platform has a suite of services that help companies plan, verify, and execute a FDI supply chain.

Location Optimization: Edon Connect platform utilizes your demand data and business requirements to build locations to meet your cost and service objectives. They can use all, some, or none of your current locations. Edon Connect will do all the hard work. You just provide the data and the business requirements.

Inventory Optimization: Edon Connect platform utilizes your demand data and business requirements to build inventory policies for all of your items. Multiple plans can be compared to pick the right plan for your cost and service requirements.

Simulator: Edon Connect will use the current demand or a what-if scenario with the network and inventory plans to run the simulation. The output of the simulation is non-deterministic, which means it’s a curve of possible results with the probability of each.

Inventory Management: Edon Connect Inventory management system allows you to track all your inventory from all your locations on your desktop. You can manage all the field users and equip them with the Edon Connect Mobile app for search and scanning capabilities.

Fulfillment: Edon Connect Mobile allows your field resources to fulfil orders in the field.

Performance Metrics: Edon Connect Performance Metrics are specifically designed for a FDI system. It breaks out failures to respond with the quickest and most appropriate corrective action.

Edon Connect Operations

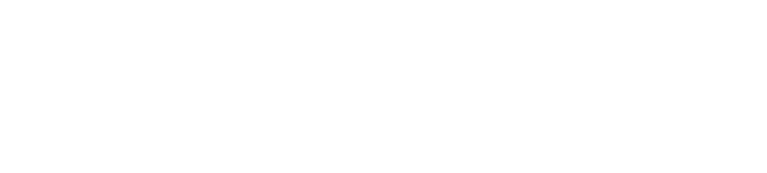

Edon Connect Operations has physical assets to execute your FDI supply chain. You can use them to supplement your current system or have us take care of all your locations.

Autonomous warehouse: If you have representatives in the field, you can have them access autonomous warehouses and have them use the Edon Connect Mobile App to manage the inventory. These locations can have remote access control and/or inventory control with RFID or Bluetooth labels.

On-site warehouse: If you are storing some of your inventory at your site or your customer’s site. Edon Connect can help you manage those items as well with Edon Connect Mobile app.

Local Delivery: Edon Connect Operations has couriers to delivery from your FDI locations. They can delivery same day or two hours or less.

Edon Connect Engagement Process

The Edon Connect Engagement process has three steps; plan, verify, execute.

Plan: Edon Connect will work with you to give you multiple options of location and inventory based on your service and cost requirements.

Verify: Edon Connect will complete a simulation to determine the robustness of the plan and the sensitivity to various changes in demand.

Execute: Edon Connect Operations has physical assets that can be utilized to manage or augment your FDI. You can also properly manage your FDI supply chain using Edon Connect performance metrics.

Contact Edon Connect

If you would like to meet with an Edon Connect Representative email them at info@edonconnect.tech or you can schedule some time on our Contact page.